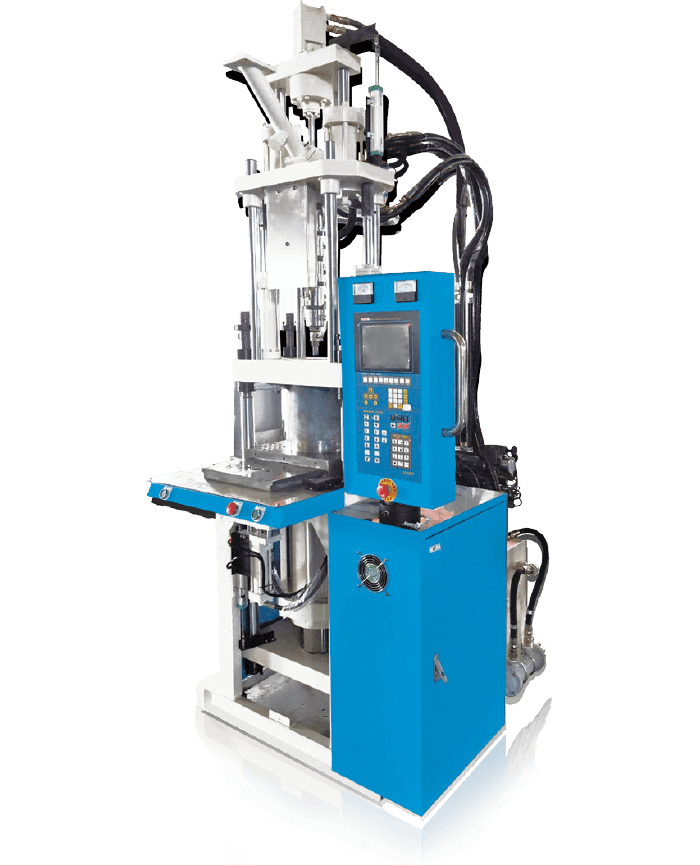

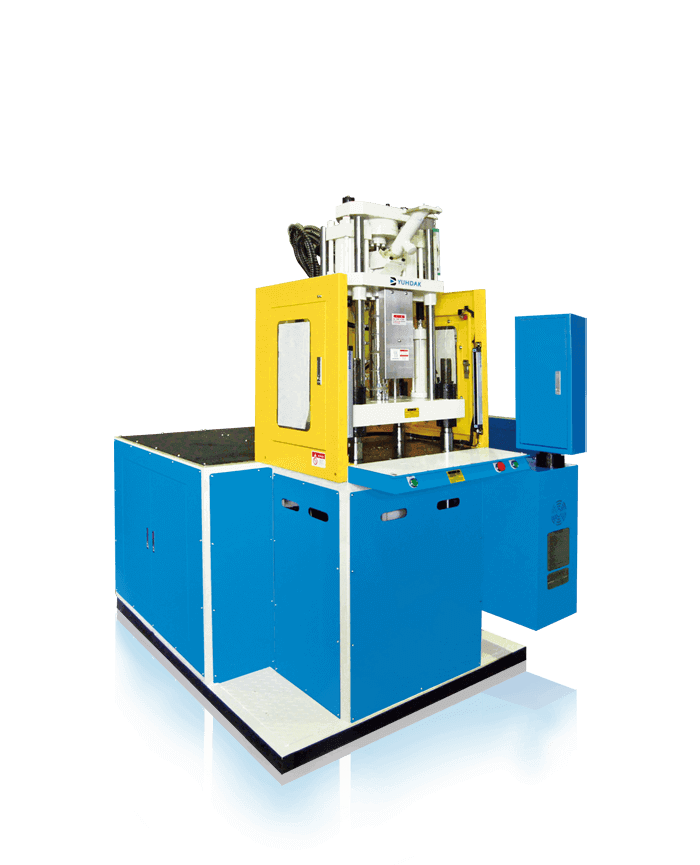

YH Series V/1S/2S

Vertical Clamping Vertical Injection Molding Machine

Product Feature

- Four-column/vertical clamping, vertical injection. Rectangular shape between tie bars for easy insert.

- Twin injection cylinder balanced for smooth and powerful injection.

- Simple structure, small occupancy.

- Double action clamping cylinder for fast clamping, slow speed high pressure clamping.

- Single sliding pushes the lower mold out for easy loading/unloading.

- Double sliding use two lower mold, machine molding the parts while the operator is loading the other mold, to increase productivity.

Related Video

Hardware & Household Items

Auto & Glass Items

Plug Series Items

Medical Items

Bakelite & LCP Items

Consumer Electronics Items

Main specifications

Swipe the table to see more informations

*Specifications are subject to change without notice.

*Screw and clamping force are optional.