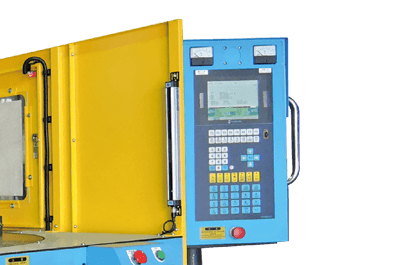

YR Series

Multiple Embedded Rotary Injection Molding Machine

Product Feature

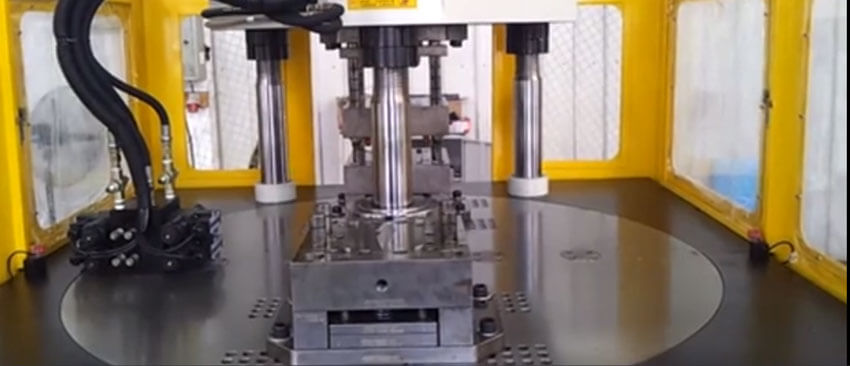

- Vertical clamping with vertical injection.

- Rotary table oscillate 180°, rotate back / forth for easy loading and finished parts pick out, to increase productivity.

- Rotary table with location pin, accurate positioning for mold alignment and automation.

- Robot interface capability for complete automation.

- Standardized with 2-station function, and capable for 3-station or 4-station function & automation linkup for advanced efficiency.

- Standardized with 3-columns clamp, and available for 4-columns clamping upon request.

Related Video

Hardware & Household Items

IMD & IML Item

Plug Series Items

Double Injection Molding Items

Consumer Electronics Items

Main specifications

Swipe the table to see more informations

*Specifications are subject to change without notice.

*Screw and clamping force are optional.