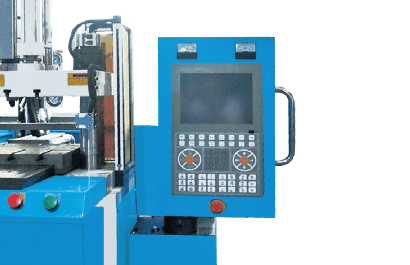

YHL Series

Vertical Plastic Injection Molding Machine

Product Feature

Vertical plastic injection molding machines are used to produce various precision plastic parts. The features of the YHL series vertical plastic injection molding machine including:

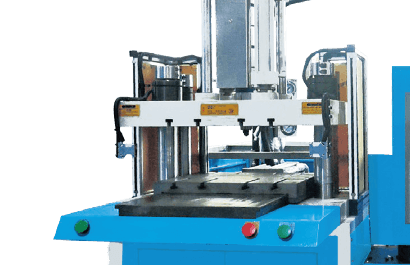

- The YHL series vertical plastic injection molding machine is designed with vertical upright clamping, straight shot structure, and simple structure.

- The design method of shooting the center shifting element makes the three-sided space more open and can be applied to the long strip-shaped automobile sealing strip to form a corner or to form a lead product, which makes the forming work easier.

- Vertical plastic injection machine, injection system adopts standard and modular design, universal injection molding of various types of inserts, and excellent plastic molding ability.

- Vertical rubber injection machine, injection system adopts screw feeding and plunger injection two-stage design, which can adapt to different hardness rubber materials, and rubber injection is stable and accurate.

- Optimized design, such as one of the most reliable injection molding equipment for clamping/injection/plasticizing.

Process of Vertical Plastic Injection Molding

Molten plastic material is vertically injected into a mold to form a specific shape. The plastic material is then cooled and solidified to create the final product. This entire process is done in a vertical direction.

Advantages of Vertical Plastic Injection Molding Machines

Vertical plastic injection molding machines offer several advantages over horizontal machines, including:

- Space-saving design: Vertical machines take up less floor space than horizontal machines, making them ideal for smaller manufacturing facilities.

- Increased accuracy: The vertical orientation of the mold and injection unit allows for more precise control over the injection process, resulting in more accurate and consistent parts.

- Reduced waste: Because the mold is clamped vertically, gravity helps to keep the molten plastic material in place during the injection process, reducing the likelihood of material waste or misalignment.

Hardware & Household Items

Plug Series Items

Bakelite & LCP Items

Consumer Electronics Items

Main specifications

Swipe the table to see more informations

*Specifications are subject to change without notice.

*Screw and clamping force are optional.